Rick Alfandre, AIA, LEED AP BD+C, President of Alfandre Architecture, PC

While many of us have built structures with heavy timber, Mass Timber takes building with wood to new heights, literally. It is important for all commercial contractors to be aware of Mass Timber. This relatively new system for building is probably coming to our marketplace soon and can revolutionize how America builds.

Mass Timber is comprised of multiple solid wood panels glued or nailed together, which provides exceptional strength and stability. It is a strong, low-carbon alternative to concrete and steel. Mass timber building designs are pioneering better places for us to live and work. New code changes that were passed for the 2021 code cycle allow mass timber buildings up to 18 stories tall.

Mass timber buildings use solid or engineered wood — such as glue-laminated timbers, cross-laminated timber panels and mass plywood panels — for their primary load-bearing structure including beams, columns, floor plates, roof plates, and exterior wall panels.

A relatively new set of advanced building systems, mass timber developments offer many benefits when compared to buildings constructed with other load-bearing material:

- They can be built on faster timelines. Faster timelines save on construction financing costs and allow for faster income from the buildings.

- Savings on materials and labor as well as a reduced construction schedule allow them to be built for lower cost.

- A high level of quality with factory-built components.

- Greater flexibility in the design of building components.

- With responsible forest management, they can improve sustainability by sequestering carbon dioxide rather than emitting it.

- They can catalyze an entirely new market in the green economy, creating well-paying jobs in cities as well as rural communities.

- They offer improved safety for construction workers, residents, and commercial tenants.

- They provide a unique aesthetic that sets them apart from other construction materials.

- The potential to expose the structural systems easily and beautifully.

- Wood stores and sequesters atmospheric carbon. It is truly an environmentally friendly, green building material.

Challenges include a more front-loaded, manufacturing-oriented approach to integrated design that requires teams of architects, engineers, contractors, and manufacturers to work closely together, and at higher levels of detail resolution.

Mass Timber Building Elements include:

GLUE-LAMINATED TIMBER

Glulam is a structural engineered wood product commonly used for beams and columns in residential and commercial applications. Glulam allows for long spans of exposed framing, as well as attention-grabbing curvatures.

CROSS-LAMINATED TIMBER

CLT is a wood panel system that is rapidly gaining in popularity in the U.S. after being widely adopted in Europe. The material’s strength, dimensional stability, and rigidity allow it to be used in mid-and high-rise construction.

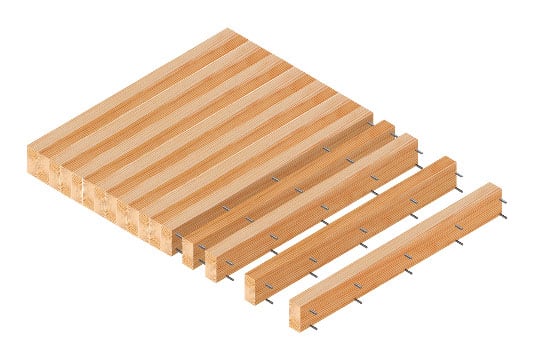

NAIL-LAMINATED TIMBER

NLT is a century-old construction method that is undergoing a design renaissance. It can be found in historical buildings as well as in new projects, where its structural performance and design elegance come together to create inspiring spaces.

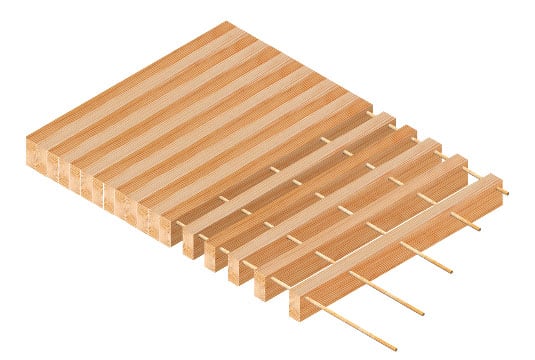

DOWEL-LAMINATED TIMBER

DLT is gaining traction for its ease of use with computer-controlled (CNC) machinery—such as lathes, routers, and mills—and its all-wood composition. DLT is similar to NLT but uses wood dowels to join boards instead of nails or screws.

CONSTRUCTION TRENDS

Tall Wood

With recent changes in building codes, and a quest to find more sustainable ways to build up, we are seeing a marked rise in the number of taller mass timber buildings popping up across North America and the globe. Buildings constructed of heavy glue-laminated timber columns and beams with cross-laminated (CLT) timber floors, walls, and roof decks are becoming more commonplace.

The 87,000 square foot John W. Oliver Design Building at the University of Massachusetts Amherst is another example of a recent finished and regionally significant mass timber building.

Hybrid Construction

Combining wood and concrete or steel in hybrid construction provides a cost-effective and sustainable solution for many occupancy types as well as improving building performance and design.

The 52,000 square foot Bullitt Center in Seattle opened in 2015 with 4 stories of mass timber above two stories of reinforced concrete and is an example of a hybrid building system.

Infill and Overbuilds

Overbuilds is a technique to add additional stories on top of an existing building, maximizing development area per square foot. Infill refers to the development of vacant lots surrounded by other, existing buildings.

Both building types are ways to address urban densification. Wood structural systems are much lighter than traditional building materials making the structural feasibility of adding stories more likely.

Design Flexibility and Exposed Structure

Fire Safety

Mass timber chars in a major fire but does not burn. Mass timber is much more stable than unprotected steel in a fire.

Conclusion

Mass Timber construction systems are becoming increasingly popular as a creative and cost-efficient way to build. All professionals working in the building trades should become familiar with the concepts of mass timber construction. Mass timber buildings are aesthetically pleasing, structurally innovative and are a great way to build sustainably.

–